AGRIGEOW

Pyrolysis is a thermochemical process that involves the decomposition of organic materials at high temperatures in the absence of oxygen. It is commonly used for converting biomass, such as agricultural waste or wood, into biochar, bio-oil, and syngas.

In the case of digestate (the residual solid portion of theanaerobic digestion of organic waste), pyrolysis can be used as a means of further treatment and valorization. Digestate typically contains a mixture of organic matter, nutrients, and potentially harmful substances. By subjecting digestate to pyrolysis, it can be transformed into valuable products while also reducing its volume and improving its stability.

Usually, during the pyrolysis process, digestate is heated to temperatures typically ranging from 350 to 800 degrees Celsius in an oxygen-limited environment. This causes the organic matter within the digestate to decompose, leading to the production of biochar, bio-oil, and syngas.

Biochar: This is a solid carbon-rich material that is similar to charcoal. It has a highly porous structure, which makes it an excellent soil amendment. Biochar can improve soil fertility, water retention, and nutrient availability, thus enhancing crop growth and reducing the need for synthetic fertilizers.

Bio-oil: Also known as pyrolysis oil or bio-crude, bio-oil is a dark-colored liquid that contains a wide range of organic compounds. It can be further refined into transportation fuels or used as a feedstock for various chemical processes.

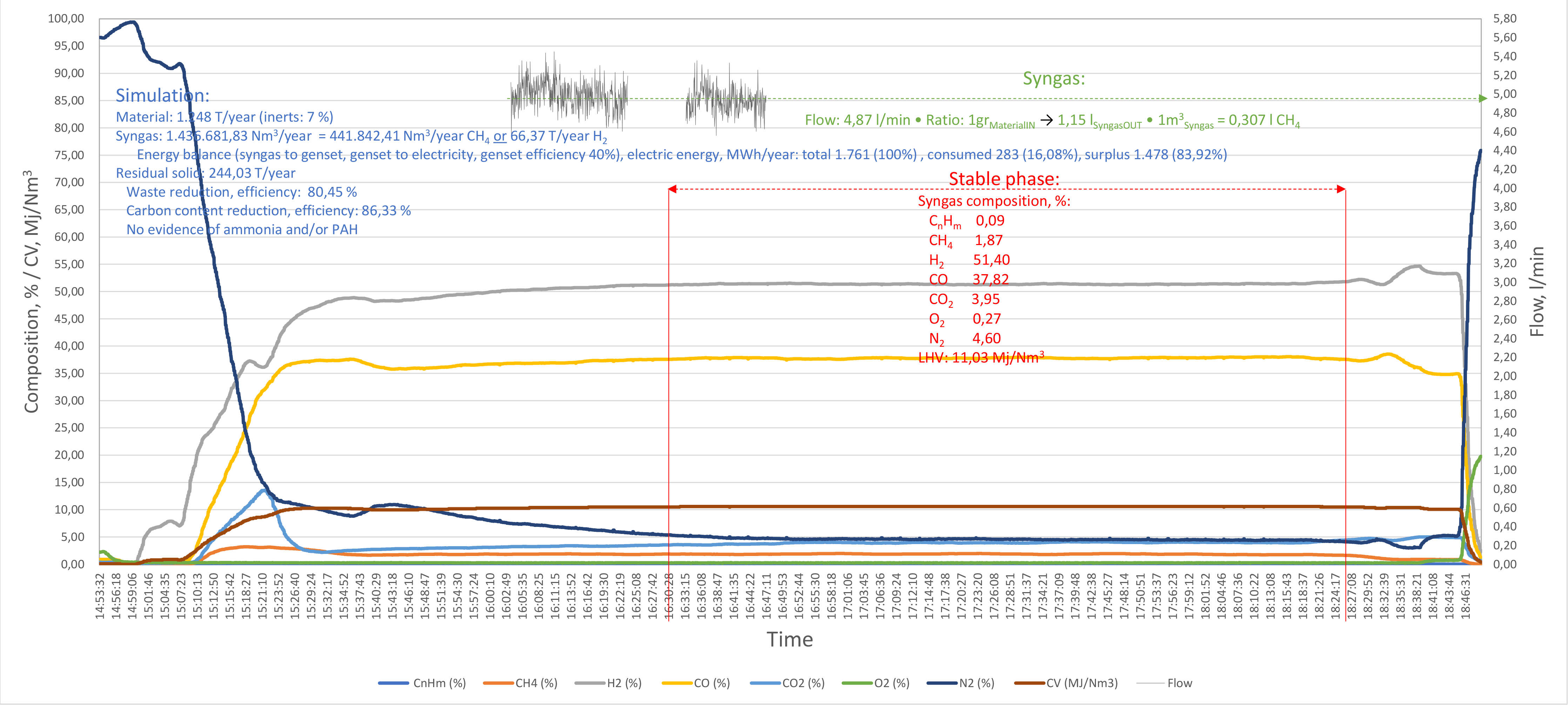

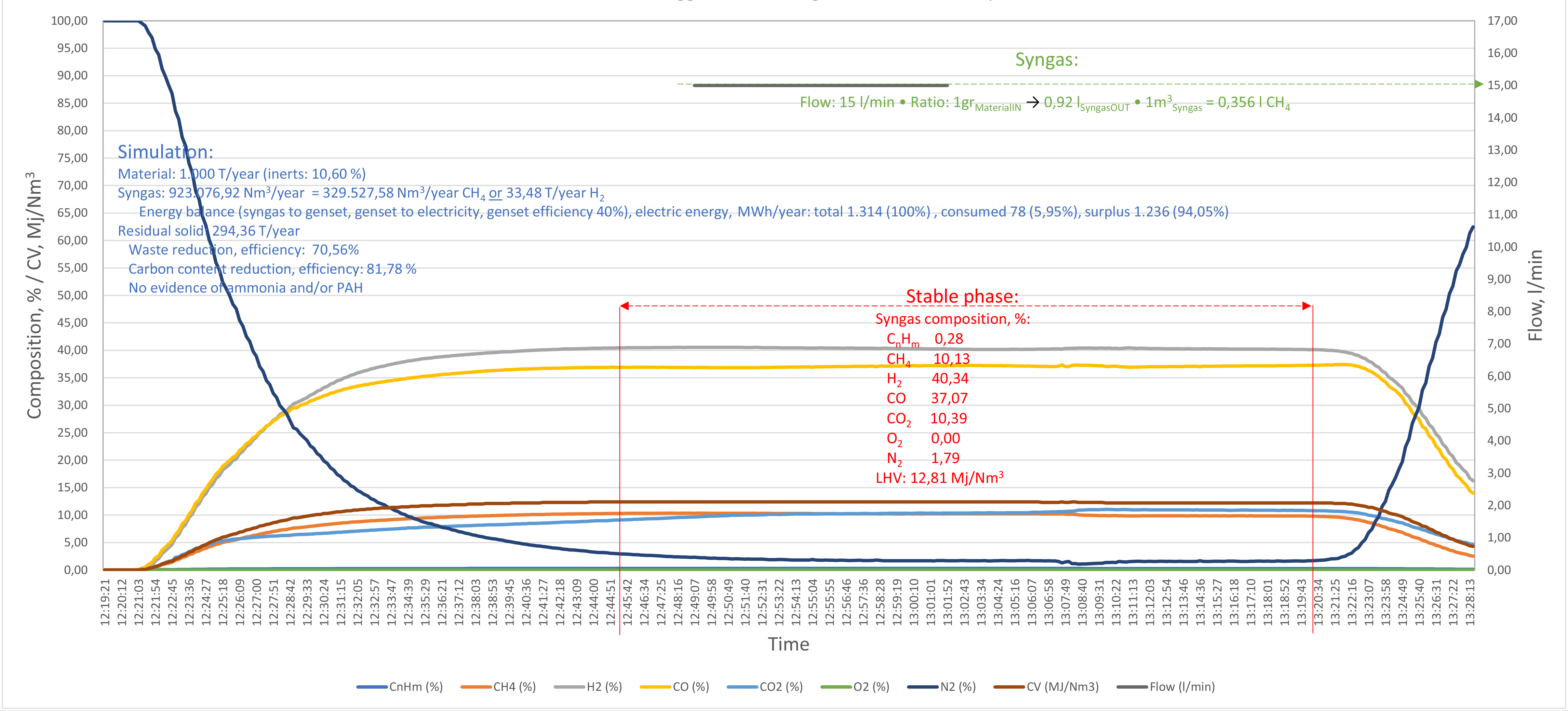

Syngas: Syngas is a mixture of carbon monoxide, hydrogen, and other gases. It can be used as a fuel for heat and power generation or further processed into valuable chemicals and fuels through gasification or other conversion technologies.

By subjecting digestate to pyrolysis, the organic matter is effectively converted into these valuable products, which can be utilized in various applications, including agriculture, energy production, and industrial processes. Additionally, pyrolysis can help in reducing the volume of digestate, making it easier to handle and transport, while also reducing the risk of potential environmental impacts associated with its disposal.

Digestate

LAMIGEOW

High-pressure laminate (HPL) is a durable and versatile material commonly used in various applications such as countertops, furniture, and wall panels: the GEOW® process can be utilized for the treatment of HPL processing wastes.

Gasification involves converting organic or carbonaceous materials into a synthesis gas (syngas) consisting primarily of hydrogen and carbon monoxide. This process occurs under high temperatures and a controlled amount of steam. Through gasification, HPL processing wastes are transformed into syngas, which can be further used as a fuel for the HPL production thermal need.

By converting HPL production wastes into useful products, the GEOW® process contributes to reducing environmental pollution, conserving resources, and promoting a circular economy approach to material utilization.

HPL Wastes